News & Media

04/25/2024 - Oliver Hagenlocher - Press

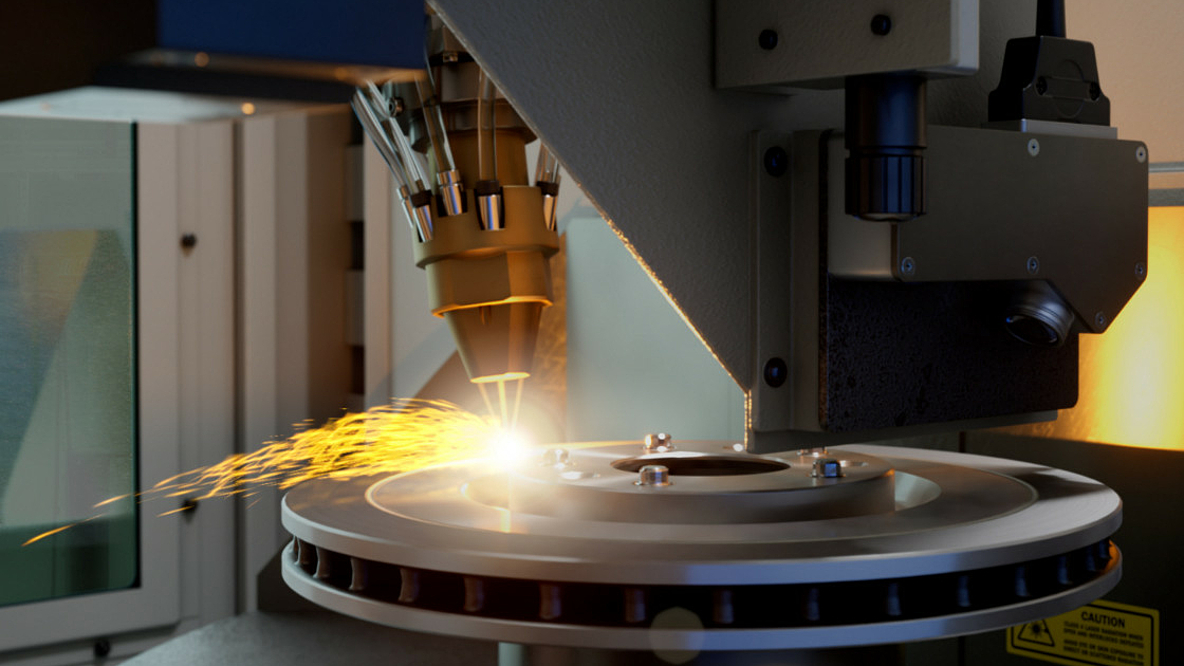

EMAG at the GrindingHub 2024 – Grinding technology for the low-emission mobility of the futureGrinding is a key technology for the resource-saving and low-emission mobility of the future. Examples of this include electric drives, which place the highest demands on the precision and surface properties of transmissions and engine components, or brake discs with reduced fine dust and hard…

04/10/2024 - Oliver Hagenlocher - Press

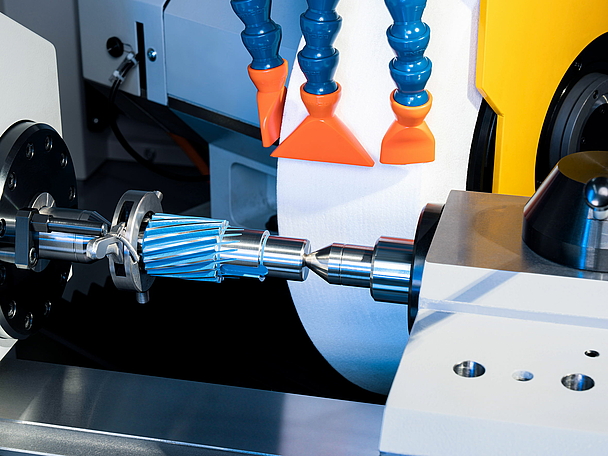

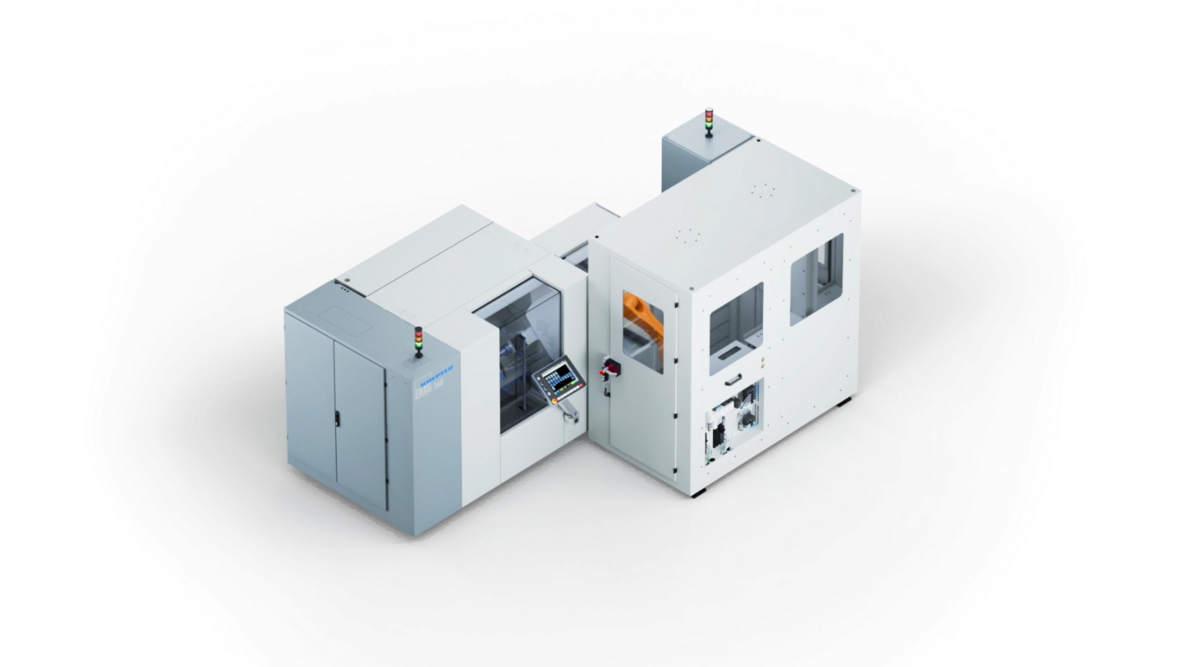

WPG 7 CNC from EMAG Weiss: Ensure rapid external grinding processes in the smallest of spacesIn many areas of application, it is uneconomical to use oversized universal cylindrical grinding machines for the external machining of smaller components - a lot of floor space is lost and the functionality is not fully utilized. With the new WPG 7 CNC external grinding machine, EMAG Weiss…

03/13/2024 - Oliver Hagenlocher - Press

EMAG is working on "green manufacturing": Pulling out all the stops for greater energy efficiencyHow important is the topic of "climate-neutral production" for industry at this moment? A recent survey conducted by the German Engineering Federation (VDMA) among its member companies provided an impressive answer. According to the survey, more than three quarters of companies have set their own…

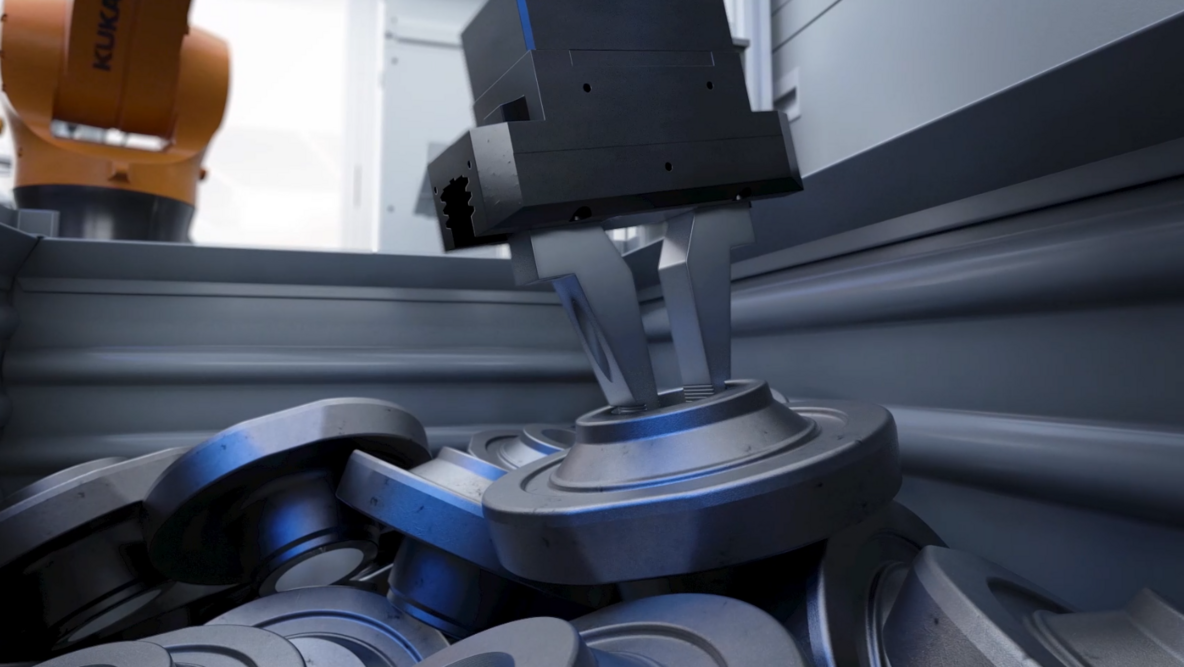

Our video highlights

We have new videos for you! Our preview list shows you all new EMAG video highlights.